About

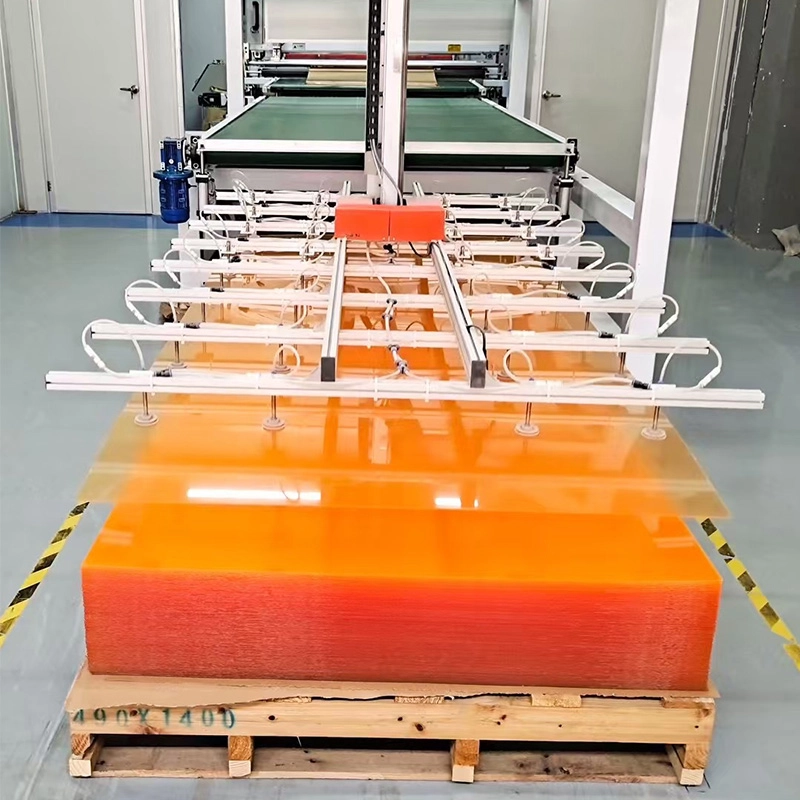

CHINAPLAS covers an area of 20,000 square meters. We specialize in manufacturing decorative acrylic material, including custom acrylic products and ABS sheets, utilizing seven imported automatic assembly systems with an annual output of 300,000 tons.

Foshan CHINAPLAS Material Co., Ltd.

Founded in 2006, Foshan CHINAPLAS Material Co., Ltd. is located in Guangdong Province, the heart of China's manufacturing industry. The company has 20,000 square meters of modern industrial park, equipped with 5 international top automated production lines, with an annual production capacity of 26,000 tons of high-end acrylic sheets.

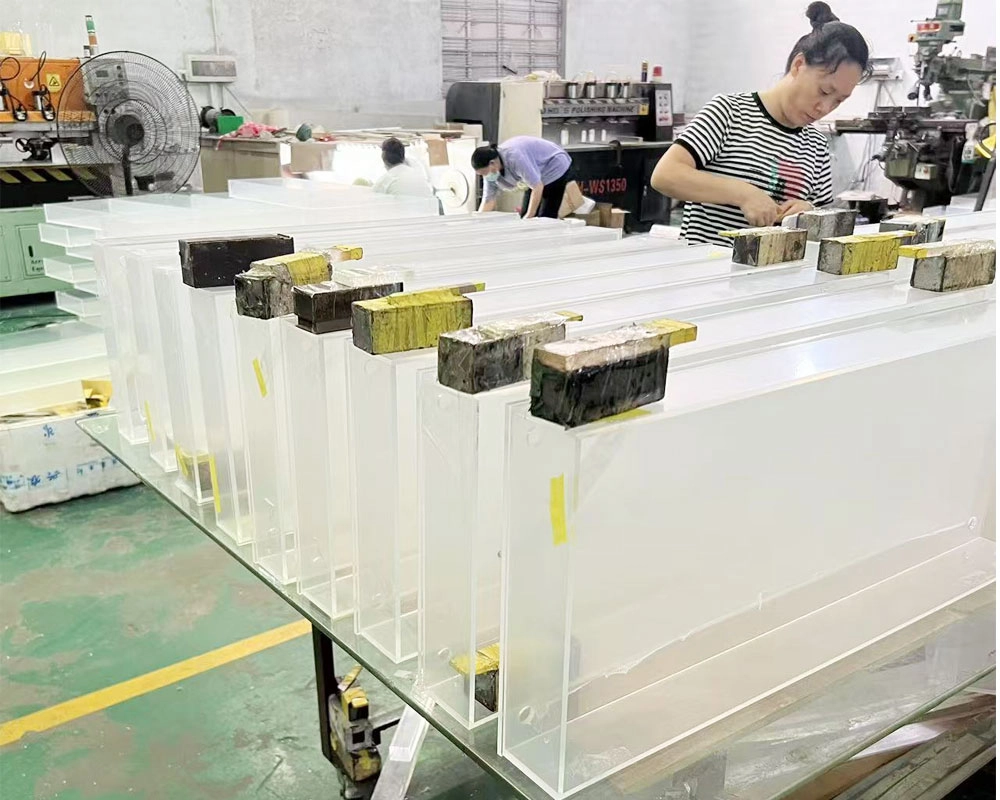

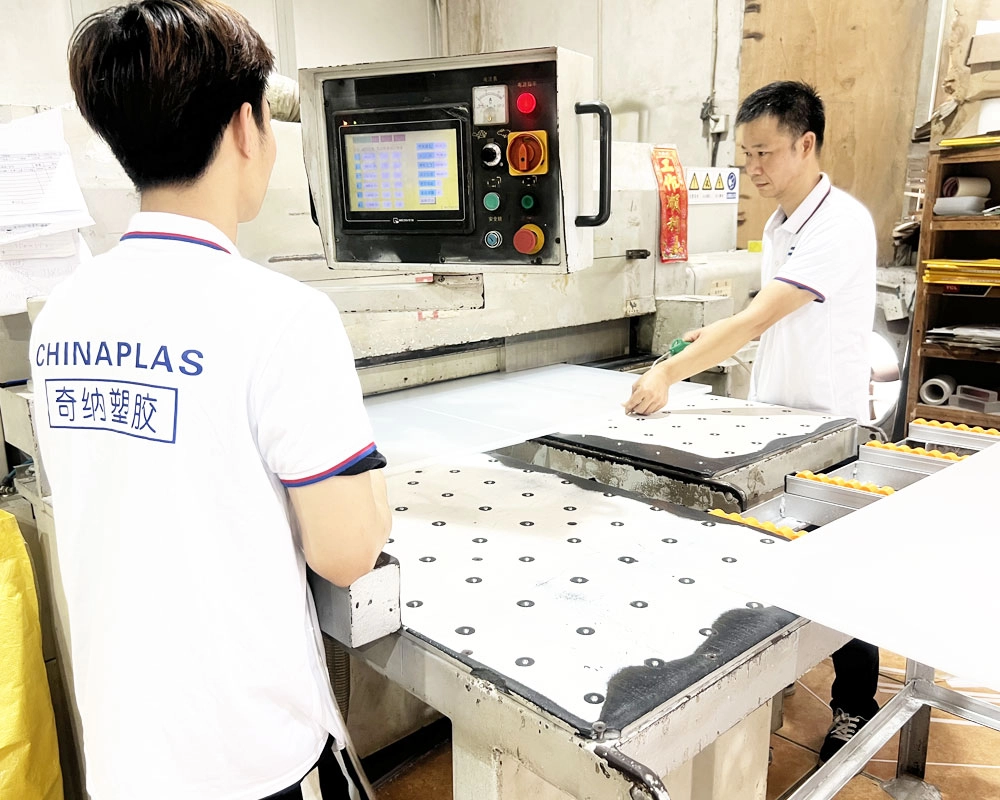

As a leading one-stop service provider in the industry, we also operate a customized processing center with more than 50 professional equipment, focusing on the precision processing of acrylic display racks, trays, storage boxes and other products, providing customers with the whole industry chain services from raw materials to finished products.

Professional Team, Shaping Excellent Quality

Our team consists of a group of engineers, designers and production personnel with extensive experience and expertise in the plastic products industry. With a deep understanding of material properties and expertise in precision manufacturing, we are able to provide customers with one-stop solutions from product design and mold development to finished product manufacturing.

The team members always uphold the concept of “quality first, customer first” and are committed to continuous innovation and optimization of production processes to ensure that each product meets high-quality standards. We not only focus on technological advancement but also on teamwork and customer communication to provide customers with efficient, reliable and customized services.

Experienced in Multiple Exhibitions, Trusted by Global Clients

We have experience in exhibiting at many domestic and international exhibitions and have showcased our customized plastic product solutions at a number of industry-specific exhibitions covering packaging, industrial, consumer goods and other sectors. Each exhibition is an important platform for us to communicate with customers face-to-face and demonstrate our innovation and quality.

Core Advantages of Choosing CHINAPLAS

Top Ingredients Guarantee

Exclusive use of optical-grade PMMA raw materials from internationally recognized brands such as Mitsubishi (Japan), Evonik (Germany) and Rohm Chemie (Germany).

Double capacity support

Two production bases operate in synergy to ensure a stable and reliable supply chain.

Craftsmanship Benchmark

Industry-leading board flatness (≤0.5 mm/m²) and excellent weathering performance (10-year warranty)

Cost Advantage

A vertically integrated production system brings highly competitive prices in the market.

Advanced Acrylic Machining for Clear, Accurate Results

Global Service Network

19+ years of industry experience

Multilingual foreign trade team of 25 people

48-hour rapid response mechanism

Service network in 50+ countries and regions around the world

Foshan CHINAPLAS Material Co., Ltd. Development History

From Local Manufacturer to Global Leader in Acrylic Solutions

2006: Founding Years

• Equipment: 5 cutting machines + 3 engraving machines, with a team of just 10 employees, primarily serving the domestic Chinese market.

• Positioning: Built early customer trust through high-precision processing and rapid response.

2010: Venturing into Global Trade

• Launched operations on Alibaba International and Made-in-China.com, initiating global sales.

• Expanded factory space to 2,800 sqm, increasing production capacity by 50%.

2013: Expanding into International Markets

• First participation in Hong Kong International Printing & Packaging Fair and Shanghai Advertising & Sign Expo, attracting numerous traders and wholesalers from Europe, the UK, the US, Southeast Asia and the Middle East.

• Overseas orders accounted for over 30% of total sales, exporting to markets like the UK, USA, Australia, Canada Malaysia, Saudi Arabia, and the UAE.

2016: Milestone Partnerships with Global Brands

• Became the designated supplier for Champagne Bollinger and Coca-Cola, providing customized high-end display solutions.

• Expanded factory space to 5,000 sqm, adding 20 new imported machines (German CNC, Japanese laser engravers).

• The team grew to 60 employees, with annual sales exceeding RMB 50 million.

2019-2020: Transformation & Breakthrough During the Pandemic

• Achieved RMB 100 million in annual sales, with export volume surging 300%.

• Strategic investment: Acquired stakes in an acrylic sheet factory (10,000+ sqm), securing full control over raw material supply.

• Workforce exceeded 100 employees, obtaining TUV, SGS, and ISO9001 certifications for international quality compliance.

2024: A New Chapter in Globalization

• Showcased products at The Big 5 Dubai, Plast Eurasia Istanbul, and Russia Build Expo, penetrating emerging markets.

• Became a core supplier for the Middle East and Eastern Europe, with overseas business now comprising 60% of total sales.

• Current scale: 20,000 sqm production base, 200+ employees, 300,000-ton annual capacity, serving 50+ countries worldwide.

• Our Core Strengths

✅ End-to-end solutions: From sheet production to finished products—one-stop service for all customer needs.

✅ International certifications: Compliant with European and American standards for safety and sustainability.

✅ Customization expertise: Full support from design to mass production, helping clients capture market opportunities.

• Moving forward, we will continue to drive innovation and create value with global partners!

2023-2025: Strategic layout

• Invested 50 million yuan to expand the intelligent storage system

• Cooperation with the Chinese Academy of Sciences to establish a new materials R&D center

• Implementation of ERP+MES digital management system

• Develop environmentally friendly recyclable acrylic composites.

Are you looking for an initial consultation, or do you have a specific project?

If you are interested in our products and services, please leave us messages here to know more details. We will reply as soon as possible.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

Foshan Chinaplas Material Co.,ltd

Foshan Chinaplas Material Company Limited

FOSHAN CHINAPLAS MATERIAL CO.,LTD

Foshan Chinaplas Material Co.,ltd

CHINAPLAS ACRYLIC

Whatsapp: +8613927780518