Customer Success Story: From Inquiry to Delivery – A Seamless Partnership Journey

At Foshan Chinaplas Material Co., Ltd., every customer relationship is built on trust, quality, and seamless service. One such success story began with a simple product inquiry and culminated in a strong international partnership.

Step 1: Initial Quotation and Communication

In early March, we received a product inquiry from a client based in the Middle East. They were looking for high-quality acrylic sheets for a large-scale interior decoration project. After understanding their specifications, we promptly sent a detailed quotation, including product options, pricing, MOQ, and lead time. Our sales representative maintained timely follow-up and responded to technical questions to build trust from the very beginning.

Step 2: On-Site Factory Visit in China

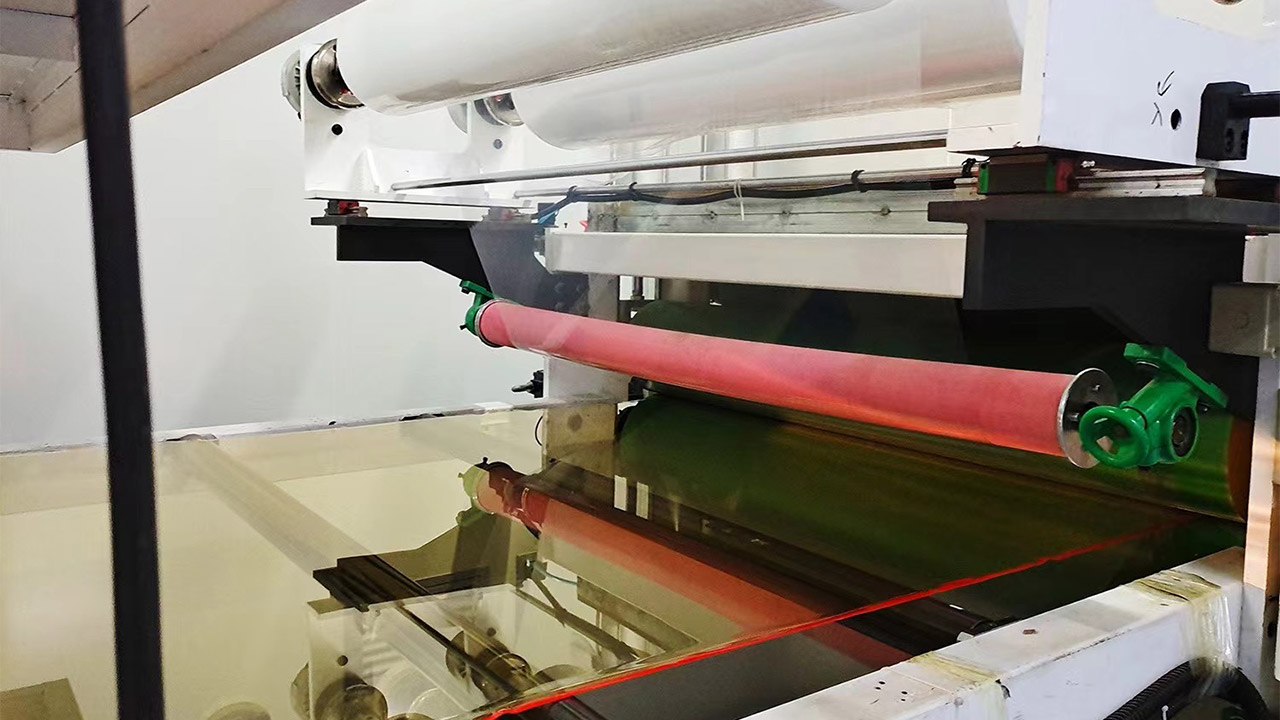

To ensure quality and reliability, the client decided to visit our manufacturing facility in Foshan. We arranged everything in advance—transportation, hotel booking, and a full factory tour. During the visit, we walked them through every step of the production process: from raw material selection to cutting, polishing, and packaging.

The client was particularly impressed by our fully automated production lines, clean workshop environment, and strict quality control procedures. Seeing the equipment and our team’s professionalism in person strengthened their confidence in our capability.

Step 3: Business Dinner – Building Trust Beyond the Factory

Following the factory tour, we invited the client to a traditional Chinese dinner in downtown Foshan. Over warm dishes and sincere conversation, we discussed not only business but also culture, family, and future plans. It was during this dinner that the client expressed how much they appreciated our hospitality and transparency—two qualities they value in long-term partners.

Step 4: Placing the Order

Just two days after their visit, the client officially confirmed the order—a full container load of customized acrylic sheets with protective masking. We quickly issued a Proforma Invoice, and the deposit was received within the same week. Production commenced immediately.

Step 5: Manufacturing & Quality Inspection

Our production team worked efficiently to meet the client’s timeline without compromising on quality. Throughout the process, we shared weekly updates with photos and videos. Before shipping, we conducted a strict inspection and provided a detailed quality report for the client’s reference.

Step 6: Loading & Shipping

After inspection approval, the goods were carefully loaded into a 40-foot container. All sheets were stacked on custom wooden pallets with edge protection to prevent any damage during transit. We coordinated with the freight forwarder to ensure timely shipping and provided the client with a full set of documents for customs clearance.

Step 7: Successful Delivery & Customer Feedback

About three weeks later, the container arrived safely at the client’s designated port. The unloading process went smoothly, and all goods arrived in perfect condition. The client sent us positive feedback, including photos of the sheets installed at their project site—proof that our materials met their high standards.

Planetary Pearls Purple Acrylic Sheet (PMMA) Fantasy Water Pattern 3MM

Abs Plastic Sheet Abs Styrene Sheets for Building Model Crafts Panel

CHINAPLAS delivers industrial-grade ABS plastic sheets—exceptionally durable, easily machinable, and highly impact-resistant. Perfect for demanding applications, find your reliable wholesale ABS sheet source for high quality and performance.

Hot Sale 0.6MM 0.8MM 1.25MM 1.3MM 1.5MM 2MM 3MM Abs Laser Engraving CNC Abs Double Color Plastic Sheet for CNC LASER Engraving

Who We Are

Foshan Chinaplas Material Co., Ltd. specializes in the design, engineering, and manufacturing of high-performance ABS dual-color injection-molded components. With over a decade of dedicated expertise, we have become a reliable partner for brands seeking seamless, durable, and visually striking plastic solutions.

Our Expertise: ABS Dual-Color Molding

We master the art and science of dual-shot molding, seamlessly integrating two colors or material grades of ABS into a single, robust part. Our process eliminates the need for secondary assembly, painting, or bonding—delivering products that are not only aesthetically superior but also structurally sound.

Key Advantages of Our Products

✅ Seamless Integration – Perfect bonding of colors/materials with no gaps, no peeling, and no assembly lines.

✅ Design Freedom – Enable complex geometries, sharp color contrasts, embedded logos, and textured finishes (soft-touch, gloss, matte).

✅ Functional Performance – Combine rigid and flexible ABS for ergonomic grips, seals, or backlight-ready sections.

✅ Durability & Lightweight – Inherit the impact resistance and strength of ABS while reducing product weight.

✅ Cost Efficiency – Lower total cost of ownership through part consolidation, reduced assembly, and streamlined production.

Our Added Value

🔹 10+ Years of Specialization – Deep process know-how in ABS dual-color molding.

🔹 End-to-End Support – From DFM (Design for Manufacturability) and prototyping to high-volume production.

🔹 Quality Commitment – Strict control over material selection, molding parameters, and final inspection.

🔹 Industry-Focused Solutions – Proven experience in consumer electronics, automotive interiors, home appliances, and industrial components.

Why Partner With Us?

At Foshan Chinaplas, we don’t just manufacture parts—we deliver integrated solutions that enhance product value, performance, and appeal. Let’s collaborate to turn your innovative ideas into reality.

ABS DUO COLOR for Advertising UV proof suitable for outdoor

Who We Are

Foshan Chinaplas Material Co., Ltd. specializes in the design, engineering, and manufacturing of high-performance ABS dual-color injection-molded components. With over a decade of dedicated expertise, we have become a reliable partner for brands seeking seamless, durable, and visually striking plastic solutions.

Our Expertise: ABS Dual-Color Molding

We master the art and science of dual-shot molding, seamlessly integrating two colors or material grades of ABS into a single, robust part. Our process eliminates the need for secondary assembly, painting, or bonding—delivering products that are not only aesthetically superior but also structurally sound.

Key Advantages of Our Products

✅ Seamless Integration – Perfect bonding of colors/materials with no gaps, no peeling, and no assembly lines.

✅ Design Freedom – Enable complex geometries, sharp color contrasts, embedded logos, and textured finishes (soft-touch, gloss, matte).

✅ Functional Performance – Combine rigid and flexible ABS for ergonomic grips, seals, or backlight-ready sections.

✅ Durability & Lightweight – Inherit the impact resistance and strength of ABS while reducing product weight.

✅ Cost Efficiency – Lower total cost of ownership through part consolidation, reduced assembly, and streamlined production.

Our Added Value

🔹 10+ Years of Specialization – Deep process know-how in ABS dual-color molding.

🔹 End-to-End Support – From DFM (Design for Manufacturability) and prototyping to high-volume production.

🔹 Quality Commitment – Strict control over material selection, molding parameters, and final inspection.

🔹 Industry-Focused Solutions – Proven experience in consumer electronics, automotive interiors, home appliances, and industrial components.

Why Partner With Us?

At Foshan Chinaplas, we don’t just manufacture parts—we deliver integrated solutions that enhance product value, performance, and appeal. Let’s collaborate to turn your innovative ideas into reality.

Are you looking for an initial consultation, or do you have a specific project?

If you are interested in our products and services, please leave us messages here to know more details. We will reply as soon as possible.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

Foshan Chinaplas Material Co.,ltd

Foshan Chinaplas Material Company Limited

FOSHAN CHINAPLAS MATERIAL CO.,LTD

Foshan Chinaplas Material Co.,ltd

CHINAPLAS ACRYLIC

Whatsapp: +8613927780518