Should You Remove the Paper on Acrylic Before Laser Cutting? Complete Guide to Preparing Acrylic for Laser Engraving

Learn whether to leave or remove the protective paper on acrylic during laser cutting. Understand how protective films affect cutting quality, engraving clarity, and surface protection for cast and extruded acrylic sheets.

- Do I Leave the Paper on Acrylic When Laser Cutting?

- 1. For Laser Engraving: Remove the Back, Keep the Front

- Why?

- 2. For Laser Cutting: Keep the Paper On Both Sides (Recommended)

- Benefits:

- 3. Types of Protective Layers: Paper vs PE Film

- Paper Masking

- PE Protective Film

- 4. Should You Remove Both Sides for Clear Engraving Through the Acrylic?

- 5. Additional Tips for Best Laser Cutting Results

- ✔ Use Cast Acrylic for Engraving

- ✔ Clean the Surface First

- ✔ Adjust Air Assist

- ✔ Test Before Production

- Conclusion

Do I Leave the Paper on Acrylic When Laser Cutting?

When processing acrylic with a laser cutter, one common question is whether you should keep the protective paper or film on the sheet. The answer depends on what type of operation you’re doing—engraving, cutting, or both.

Below is a detailed guide to help you achieve the best quality, cleanest edges, and scratch-free results.

1. For Laser Engraving: Remove the Back, Keep the Front

For engraving on the front surface:

-

Remove the paper/protective film on the back side

-

Keep the protective layer on the front

Why?

✔ The back layer absorbs heat and can cause reduced engraving clarity

✔ Removing the back allows the laser to engrave cleanly

✔ Keeping the front protection prevents scratches and fingerprints during handling

✔ The remaining layer protects the engraving surface from smoke stains

This method ensures sharp, clean, frosty engravings, especially on cast acrylic.

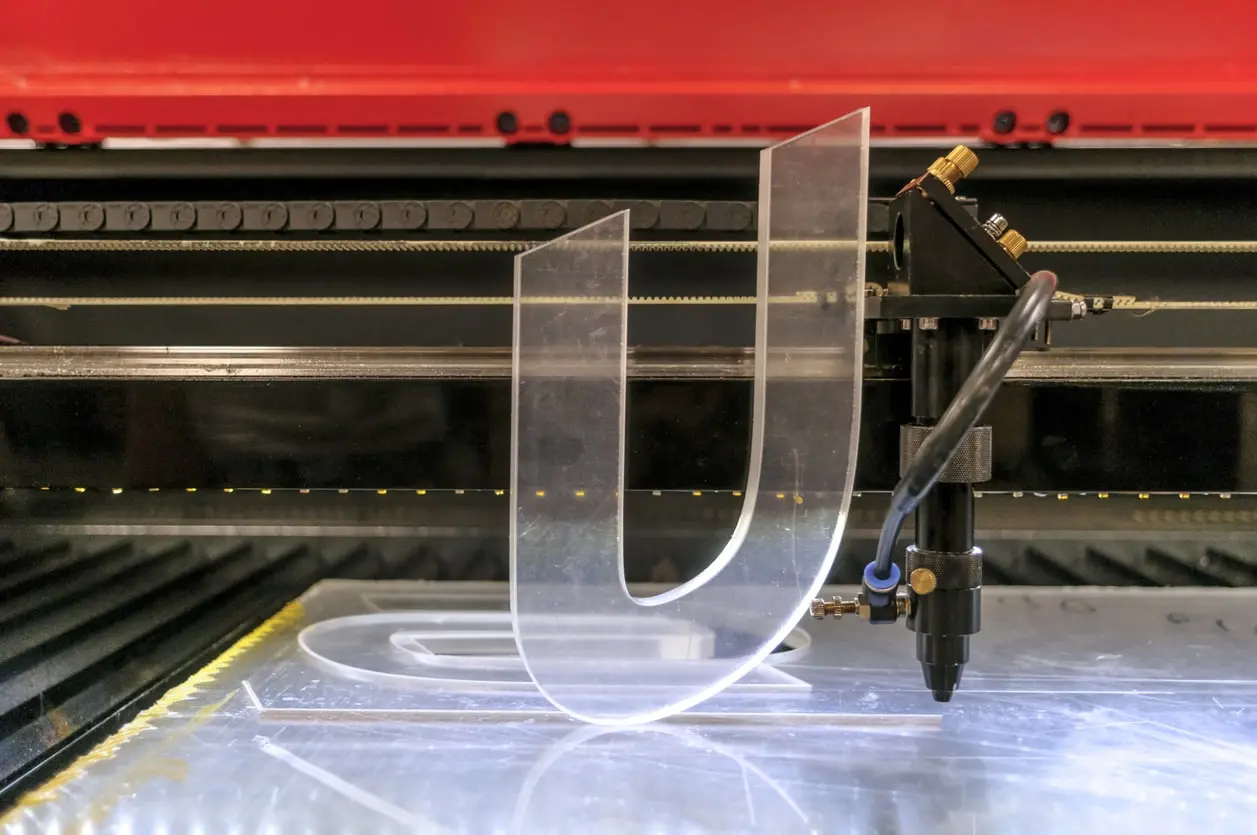

2. For Laser Cutting: Keep the Paper On Both Sides (Recommended)

When laser cutting acrylic shapes:

-

It is useful to leave the protective paper or PE film on both sides

Benefits:

✔ Prevents smoke marks around the cutting edge

✔ Protects the sheet from scratches during machine handling

✔ Reduces flaming and melting with certain laser settings

✔ Helps maintain a clean, polished edge finish

Many laser workshops cut cast acrylic with both sides masked for the best results.

3. Types of Protective Layers: Paper vs PE Film

Acrylic sheets typically come with:

Paper Masking

-

Ideal for laser cutting

-

Heat-resistant

-

Produces cleaner cuts

-

Easy to remove after engraving

PE Protective Film

-

Suitable for CNC routing

-

May melt slightly during laser cutting

-

Should be tested before use on high-power lasers

If PE film melts, simply remove it before cutting.

4. Should You Remove Both Sides for Clear Engraving Through the Acrylic?

Yes.

If you are engraving from the back through the acrylic (often used for reverse-engraving LED signs):

-

Remove both protective layers

-

Engrave directly onto the backside

-

Flip the sheet so the image is viewed through the clear surface

This technique gives a premium, glossy finish with protected engravings inside.

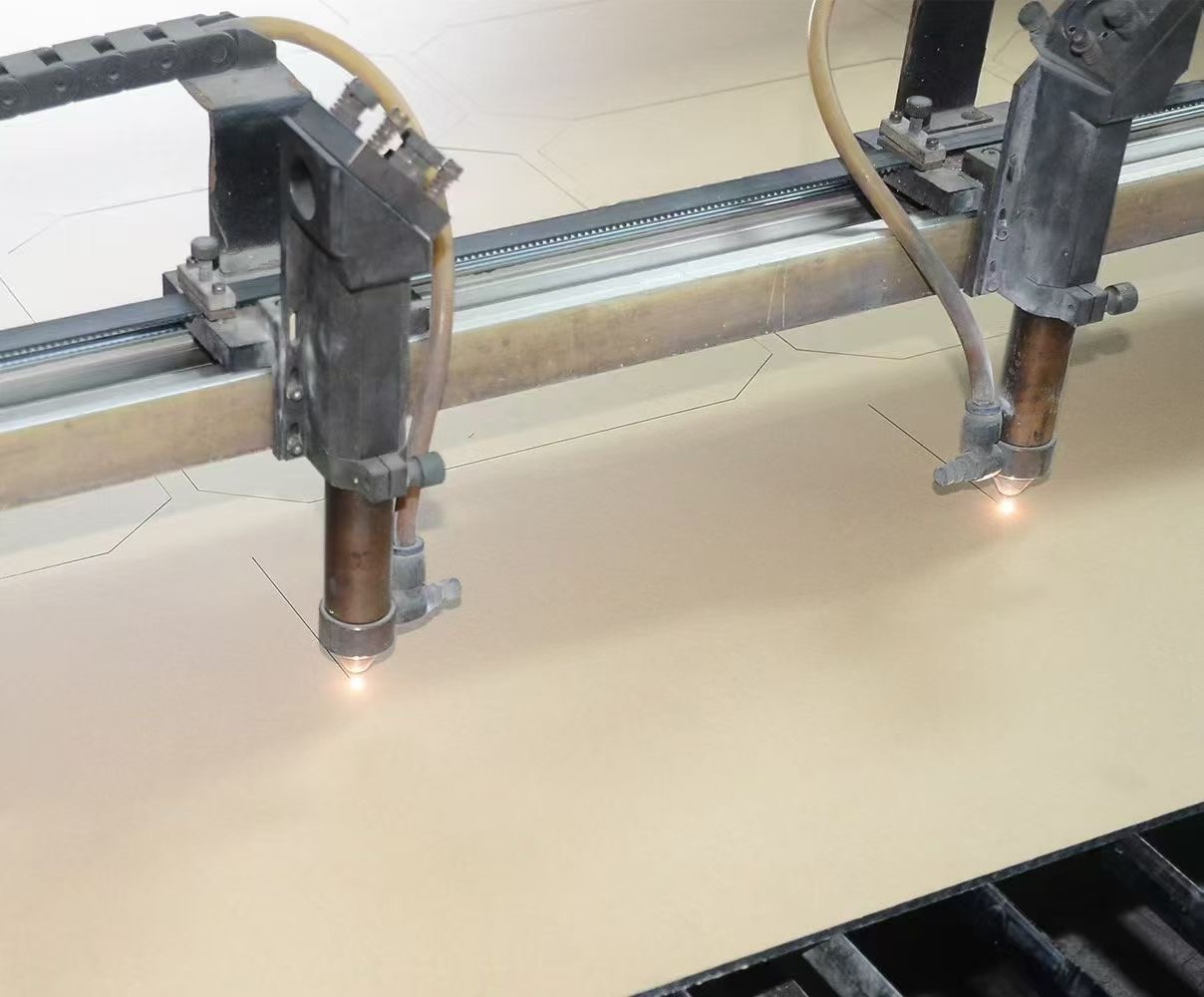

5. Additional Tips for Best Laser Cutting Results

✔ Use Cast Acrylic for Engraving

Cast acrylic produces a beautiful white frosty engraving.

✔ Clean the Surface First

Dust or fingerprints under the masking can cause heat spots.

✔ Adjust Air Assist

Too much air can blow masking paper into the beam; too little may allow flaming.

✔ Test Before Production

Different brands of acrylic may have paper types with varying heat resistance.

Conclusion

Whether to leave the protective paper on acrylic during laser cutting depends on the job:

| Task | Front Masking | Back Masking |

|---|---|---|

| Engraving (front) | Keep on | Remove |

| Cutting only | Keep on | Keep on |

| Reverse engraving (back) | Remove | Remove |

By preparing your acrylic correctly, you ensure:

-

Cleaner cuts

-

Clearer engravings

-

Fewer burn marks

-

Better protection during handling

Proper masking is one of the simplest yet most important steps to achieving professional laser-cut acrylic results.

Recommended for you

Our Factory Showcases Premium Acrylic Sheets & Acrylic Products at the Dubai Building Materials Exhibition 2025

Perspex vs Acrylic: What’s the Difference? Complete Guide to Acrylic Sheets and PMMA Materials

What Are the Cons of Acrylic Mirrors? | Acrylic Mirror Sheet Guide

Indian Long-Term Client Visits Our Factory After Canton Fair — Trust Built Over Years

Kazakhstan Clients Visit Our Factory and Place Trial Order of 2,000 Mirror Acrylic Sheets

3D acrylic letter sign

Are these signs suitable for outdoor use?

Definitely. Our acrylic is UV-resistant and weatherproof.

How soon can I receive my order?

Most custom orders can be shipped within 7 working days.

Color Acrylic Sheet

Will there be batch color variations?

Our intelligent color system keeps ΔE<1.5 between batches.

Payment & Terms

What payment methods do you accept?

Acrylic LED Lightbox Signs

Do you support OEM/ODM projects?

Yes, we accept OEM/ODM orders with fast prototyping available.

Chinaplas Glitter Cast Acrylic Sheet Flake Embedded Cut 3mm Decoration DIY LASER Cutting Bending Acrylic Sheet

1220x2440mm 0.7mm 0.75mm 0.8mm 1mm Gold Mirror Acrylic Sheet for Laser Cutting

Factory supplier of 1220x2440mm 0.7–1mm gold mirror acrylic sheets for laser cutting, advertising, building decoration, weddings, dressing mirrors, and rear-view mirrors. We offer bulk production, customization, printing, and Amazon FBA direct delivery.

Wholesale Eco-Friendly 1.5mm 3mm Golden Luxury Acrylic Board Home Decor Gold Mirror Acrylic Sheets For Laser Cutting

Buy eco-friendly golden acrylic mirror sheets at wholesale prices. Available in 1.5mm & 3mm thickness, perfect for home décor, crafts, wedding decoration, signage, and laser cutting projects.

Custom CNC Cut and Laser Cut Service Transparent 1mm 3mm 5mm 8mm Clear Extruded Acrylic Sheet

Our Clear Extruded Acrylic Sheet with custom CNC cutting and laser cutting service is designed to meet diverse project requirements in signage, displays, decoration, and industrial applications. Made from 100% virgin PMMA (polymethyl methacrylate), the sheets feature excellent optical clarity, impact resistance, and smooth surfaces for precision machining.

Available in 1mm, 3mm, 5mm, 8mm thickness options, these transparent extruded acrylic sheets can be tailored to any shape, size, or design. The CNC cutting ensures high dimensional accuracy for complex shapes, while laser cutting delivers polished edges and detailed patterns without additional finishing.

This combination of premium material and precision processing makes it ideal for both professional fabrication and DIY creative projects.

Are you looking for an initial consultation, or do you have a specific project?

If you are interested our products and services, please leave us messages here to know more details. We will reply as soon as possible.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

Foshan Chinaplas Material Co.,ltd

Foshan Chinaplas Material Company Limited

FOSHAN CHINAPLAS MATERIAL CO.,LTD

Foshan Chinaplas Material Co.,ltd

CHINAPLAS ACRYLIC

Whatsapp: +8613927780518