CNC Acrylic Machining: The Ultimate Guide for Precision Plastic Parts

Acrylic (PMMA) is one of the most widely used transparent plastics in CNC systems, offering superior advantages over polycarbonate and glass. Its versatility makes it ideal for industries ranging from automotive to medical. This guide covers everything from material properties to machining best practices.

What is Acrylic (PMMA)?

Acrylic, or poly(methyl methacrylate) (PMMA), is a rigid, transparent thermoplastic. Known as a shatter-resistant alternative to glass, it’s available in pellets, sheets, or extruded forms. Key features include:

· High optical clarity (92% light transmission)

· UV stability for outdoor use

· Recyclability and chemical resistance

Why Choose CNC for Acrylic Machining?

CNC machining delivers precision-cut acrylic parts with:

✔ Tight tolerances (±0.1mm)

✔ Smooth edges (minimal post-processing)

✔ Complex geometries (laser cutting, milling, engraving)

Acrylic Properties for CNC

|

Property |

Value |

Advantage |

|

Density |

1.17–1.20 g/cm³ |

Lightweight yet durable |

|

Surface Hardness |

85–105 Rockwell M |

Scratch-resistant |

|

Thermal Expansion |

0.07mm/m·°C |

Requires machining compensation |

CNC Acrylic Machining Processes

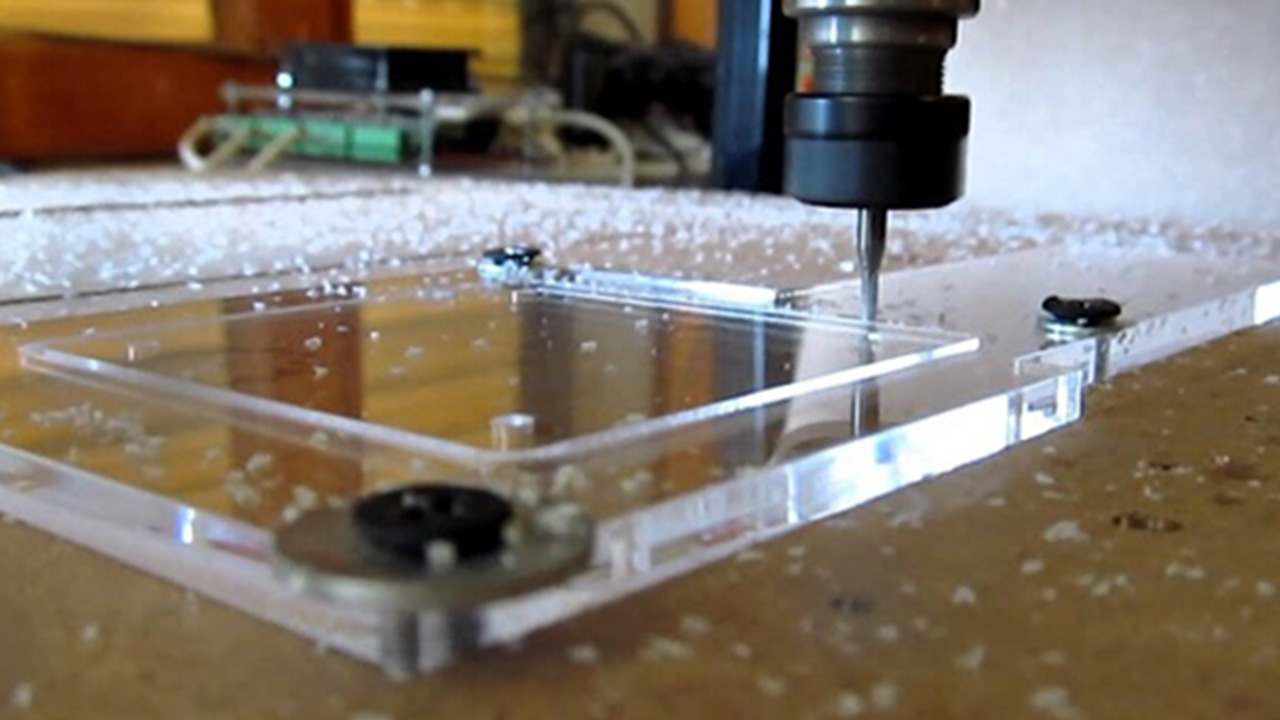

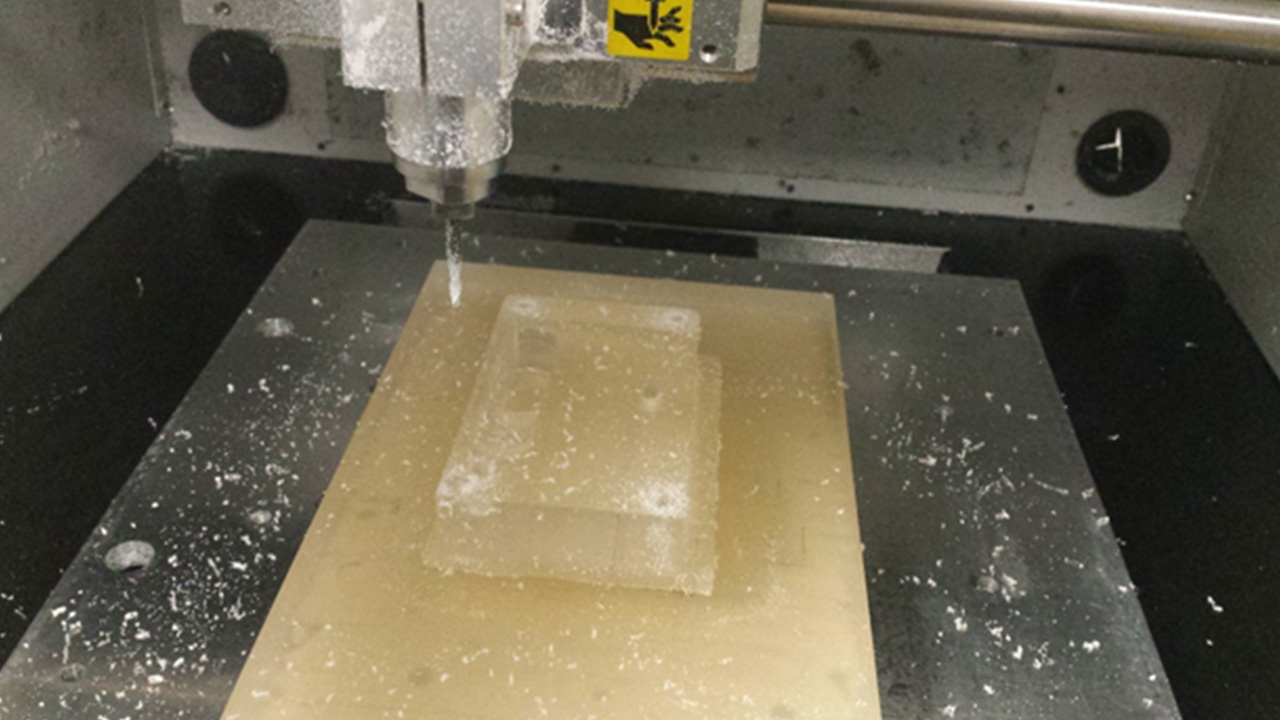

1. CNC Milling & Routing

· Best for: Signage, displays, prototypes

· Tool Tip: Use single-flute carbide bits to reduce melting.

2. Laser Cutting

· Best for: Intricate designs (e.g., retail fixtures)

· Settings: Low heat input prevents edge yellowing.

3. Injection Molding

· Best for: High-volume parts (e.g., lenses, knobs)

· Mold Design: Include draft angles (1–2°) for easy release.

Top 5 CNC Acrylic Machining Tips

1. Minimize Heat Buildup

2. Use compressed air to cool cuts. Optimize feed rates (e.g., 1.5 m/min for 3mm sheets).

3. Avoid Cracking

4. Drill holes ≥3x material thickness from edges. Anneal parts post-machining for stress relief.

5. Achieve Optical Clarity

6. Polish edges with flame polishing or diamond buffing.

7. Select the Right Acrylic Type

8. Extruded: Cost-effective for simple shapes. Cell-cast: Superior for precision optics.

9. Use Solvent Bonding for seamless joints (e.g., Weld-On #4).

10. Applications of CNC Acrylic Parts

|

Industry |

Uses |

|

Automotive |

Tail lights, dashboards, windshields |

|

Medical |

Incubators, surgical tools, dentures |

|

Architecture |

Skylights, sound barriers, facade panels |

|

Retail |

Display cases, POS stands, signage |

Recommended for you

Our Factory Showcases Premium Acrylic Sheets & Acrylic Products at the Dubai Building Materials Exhibition 2025

Should You Remove the Paper on Acrylic Before Laser Cutting? Complete Guide to Preparing Acrylic for Laser Engraving

Perspex vs Acrylic: What’s the Difference? Complete Guide to Acrylic Sheets and PMMA Materials

What Are the Cons of Acrylic Mirrors? | Acrylic Mirror Sheet Guide

Indian Long-Term Client Visits Our Factory After Canton Fair — Trust Built Over Years

Acrylic LED Lightbox Signs

Do you support OEM/ODM projects?

Yes, we accept OEM/ODM orders with fast prototyping available.

Can I customize the size and color?

Yes, we offer full customization on size, thickness, and color to meet your needs.

FAQs

What customization services do you support? What is the specific process?

We provide full-process ODM/OEM service, from design, material selection to production and processing in one-stop, support customization with drawings and samples, and professional team to follow up the whole process.

What is the minimum order quantity (MOQ) for customized orders?

Adjusted according to the type of material and process complexity, MOQ for regular products can be as low as 1 ton, small batch customization is welcome to inquire.

Orders & Pricing

Do you offer bulk discounts?

Planetary Pearls Purple Acrylic Sheet (PMMA) Fantasy Water Pattern 3MM

Abs Plastic Sheet Abs Styrene Sheets for Building Model Crafts Panel

CHINAPLAS delivers industrial-grade ABS plastic sheets—exceptionally durable, easily machinable, and highly impact-resistant. Perfect for demanding applications, find your reliable wholesale ABS sheet source for high quality and performance.

Hot Sale 0.6MM 0.8MM 1.25MM 1.3MM 1.5MM 2MM 3MM Abs Laser Engraving CNC Abs Double Color Plastic Sheet for CNC LASER Engraving

Who We Are

Foshan Chinaplas Material Co., Ltd. specializes in the design, engineering, and manufacturing of high-performance ABS dual-color injection-molded components. With over a decade of dedicated expertise, we have become a reliable partner for brands seeking seamless, durable, and visually striking plastic solutions.

Our Expertise: ABS Dual-Color Molding

We master the art and science of dual-shot molding, seamlessly integrating two colors or material grades of ABS into a single, robust part. Our process eliminates the need for secondary assembly, painting, or bonding—delivering products that are not only aesthetically superior but also structurally sound.

Key Advantages of Our Products

✅ Seamless Integration – Perfect bonding of colors/materials with no gaps, no peeling, and no assembly lines.

✅ Design Freedom – Enable complex geometries, sharp color contrasts, embedded logos, and textured finishes (soft-touch, gloss, matte).

✅ Functional Performance – Combine rigid and flexible ABS for ergonomic grips, seals, or backlight-ready sections.

✅ Durability & Lightweight – Inherit the impact resistance and strength of ABS while reducing product weight.

✅ Cost Efficiency – Lower total cost of ownership through part consolidation, reduced assembly, and streamlined production.

Our Added Value

🔹 10+ Years of Specialization – Deep process know-how in ABS dual-color molding.

🔹 End-to-End Support – From DFM (Design for Manufacturability) and prototyping to high-volume production.

🔹 Quality Commitment – Strict control over material selection, molding parameters, and final inspection.

🔹 Industry-Focused Solutions – Proven experience in consumer electronics, automotive interiors, home appliances, and industrial components.

Why Partner With Us?

At Foshan Chinaplas, we don’t just manufacture parts—we deliver integrated solutions that enhance product value, performance, and appeal. Let’s collaborate to turn your innovative ideas into reality.

ABS DUO COLOR for Advertising UV proof suitable for outdoor

Who We Are

Foshan Chinaplas Material Co., Ltd. specializes in the design, engineering, and manufacturing of high-performance ABS dual-color injection-molded components. With over a decade of dedicated expertise, we have become a reliable partner for brands seeking seamless, durable, and visually striking plastic solutions.

Our Expertise: ABS Dual-Color Molding

We master the art and science of dual-shot molding, seamlessly integrating two colors or material grades of ABS into a single, robust part. Our process eliminates the need for secondary assembly, painting, or bonding—delivering products that are not only aesthetically superior but also structurally sound.

Key Advantages of Our Products

✅ Seamless Integration – Perfect bonding of colors/materials with no gaps, no peeling, and no assembly lines.

✅ Design Freedom – Enable complex geometries, sharp color contrasts, embedded logos, and textured finishes (soft-touch, gloss, matte).

✅ Functional Performance – Combine rigid and flexible ABS for ergonomic grips, seals, or backlight-ready sections.

✅ Durability & Lightweight – Inherit the impact resistance and strength of ABS while reducing product weight.

✅ Cost Efficiency – Lower total cost of ownership through part consolidation, reduced assembly, and streamlined production.

Our Added Value

🔹 10+ Years of Specialization – Deep process know-how in ABS dual-color molding.

🔹 End-to-End Support – From DFM (Design for Manufacturability) and prototyping to high-volume production.

🔹 Quality Commitment – Strict control over material selection, molding parameters, and final inspection.

🔹 Industry-Focused Solutions – Proven experience in consumer electronics, automotive interiors, home appliances, and industrial components.

Why Partner With Us?

At Foshan Chinaplas, we don’t just manufacture parts—we deliver integrated solutions that enhance product value, performance, and appeal. Let’s collaborate to turn your innovative ideas into reality.

Are you looking for an initial consultation, or do you have a specific project?

If you are interested our products and services, please leave us messages here to know more details. We will reply as soon as possible.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

Foshan Chinaplas Material Co.,ltd

Foshan Chinaplas Material Company Limited

FOSHAN CHINAPLAS MATERIAL CO.,LTD

Foshan Chinaplas Material Co.,ltd

CHINAPLAS ACRYLIC

Whatsapp: +8613927780518