What Type of Acrylic is Used for Laser Cutting?| Best Acrylic Sheets for Laser Cutting

Learn which type of acrylic sheet is best for laser cutting. Understand the difference between cast and extruded acrylic, their performance in laser cutting, and how to choose the right material for your project.

- What Type of Acrylic is Used for Laser Cutting?

- 1. The Two Main Types of Acrylic: Cast vs Extruded

- Cast Acrylic (Cell Cast Acrylic)

- Extruded Acrylic (Continuous Cast Acrylic)

- 2. Why Cast Acrylic is Better for Laser Cutting

- 3. Ideal Acrylic Thickness for Laser Cutting

- 4. Tips for Laser Cutting Acrylic Sheets

- 5. Applications of Laser-Cut Acrylic

- 6. Conclusion: Choose Cast Acrylic for Best Laser Results

What Type of Acrylic is Used for Laser Cutting?

Acrylic is one of the most popular materials used in laser cutting and engraving. It’s widely chosen by makers, manufacturers, and artists for its clarity, smooth cutting edges, and versatility. However, not all acrylic sheets are created equal when it comes to laser processing. The two main types—cast acrylic and extruded acrylic—react differently under a laser. Understanding their differences will help you choose the right one for your specific project.

1. The Two Main Types of Acrylic: Cast vs Extruded

Cast Acrylic (Cell Cast Acrylic)

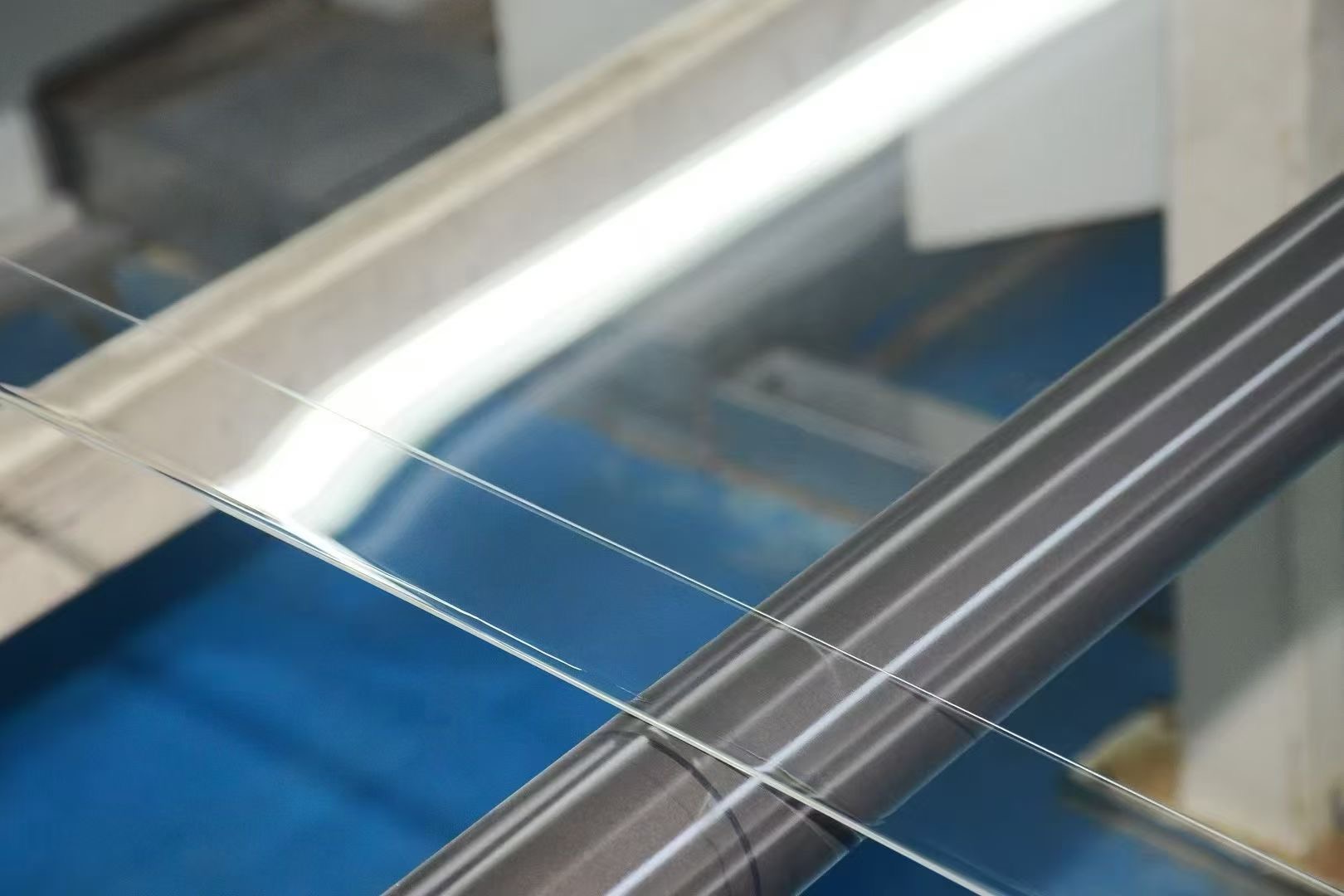

Cast acrylic, also known as cell-cast acrylic, is produced by pouring liquid methyl methacrylate (MMA) into molds. The result is a high-quality sheet with excellent optical clarity and uniform hardness.

Key features of cast acrylic:

-

Smooth, flame-polished edges after laser cutting

-

Excellent engraving contrast (white frosted finish)

-

More rigid and scratch-resistant

-

Available in a wide range of colors and thicknesses

Because of these characteristics, cast acrylic is the preferred choice for laser cutting and engraving. It produces clean cuts and beautifully frosted engraved marks, making it ideal for signage, awards, display cases, and custom nameplates.

Extruded Acrylic (Continuous Cast Acrylic)

Extruded acrylic is made by continuously pushing acrylic resin through a die to form sheets. This manufacturing process makes it more economical and consistent in thickness.

Key features of extruded acrylic:

-

Lower cost than cast acrylic

-

Smoother surface and more uniform thickness

-

Softer and easier to machine

-

Less suitable for engraving — engravings appear transparent rather than frosted

When laser cutting, extruded acrylic tends to melt slightly, producing edges that may be less clear. It’s best used for applications where engraving quality is not the main concern, such as protective covers, light diffusers, or general cutting projects.

2. Why Cast Acrylic is Better for Laser Cutting

If your goal is precision and visual quality, cast acrylic outperforms extruded acrylic in nearly every way for laser use.

| Property | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Laser Cutting Edge | Smooth and polished | Slightly melted or rough |

| Engraving Quality | Frosted white effect | Clear, less visible |

| Cost | Higher | Lower |

| Consistency in Thickness | Slight variation | Very consistent |

| Recommended Use | Signage, displays, awards | Simple cut shapes, covers |

In short, choose cast acrylic if you want perfect polished edges and high-contrast engraving. Extruded acrylic can be used for simple cutting tasks where cost and uniformity are more important than engraving appearance.

3. Ideal Acrylic Thickness for Laser Cutting

The most commonly used acrylic thicknesses for laser cutting are:

-

2mm to 6mm: perfect for small signage, model making, and craft projects

-

8mm to 12mm: suitable for larger signage, display panels, and furniture components

-

15mm and above: used for decorative installations or structural applications

Always ensure your laser cutter has enough power (at least 60–100W) to handle thicker acrylic sheets for clean, single-pass cuts.

4. Tips for Laser Cutting Acrylic Sheets

To achieve the best results:

-

Use protective film during cutting to avoid scratches and burn marks.

-

Adjust laser power and speed depending on thickness—too much power can cause melting.

-

Use air assist to blow away fumes and debris from the cutting area.

-

Engrave on the back side for a more professional, mirror-finish appearance when viewed from the front.

-

Always use cast acrylic for high-quality engraving and smooth, polished edges.

-

5. Applications of Laser-Cut Acrylic

Laser-cut acrylic is widely used in various industries, including:

-

Signage and Display: illuminated logos, nameplates, and letters

-

Home Decoration: wall art, photo frames, and furniture accents

-

Retail & Exhibition: product display stands and brochure holders

-

Awards & Trophies: precision-engraved plaques with frosted logos

-

DIY & Crafts: custom gifts, keychains, and art projects

-

6. Conclusion: Choose Cast Acrylic for Best Laser Results

When it comes to laser cutting acrylic, your choice of material determines the final quality of your product. Cast acrylic delivers professional results—clear edges, frosted engravings, and durable finishes—making it the go-to option for most laser cutting and engraving projects.

Meanwhile, extruded acrylic remains a budget-friendly option for simple cutting applications that don’t require engraving detail or perfect edge quality.

So, whether you’re crafting retail displays, architectural models, or custom signage, selecting the right type of acrylic ensures clean cuts, flawless edges, and lasting visual appeal.

Recommended for you

Our Factory Showcases Premium Acrylic Sheets & Acrylic Products at the Dubai Building Materials Exhibition 2025

Should You Remove the Paper on Acrylic Before Laser Cutting? Complete Guide to Preparing Acrylic for Laser Engraving

Perspex vs Acrylic: What’s the Difference? Complete Guide to Acrylic Sheets and PMMA Materials

What Are the Cons of Acrylic Mirrors? | Acrylic Mirror Sheet Guide

Indian Long-Term Client Visits Our Factory After Canton Fair — Trust Built Over Years

Glitter Acrylic Sheet

Can glitter acrylic be used outdoors?

Yes, with our UV-resistant option (5-year color guarantee).

Orders & Pricing

Do you offer bulk discounts?

FAQs

What customization services do you support? What is the specific process?

We provide full-process ODM/OEM service, from design, material selection to production and processing in one-stop, support customization with drawings and samples, and professional team to follow up the whole process.

Acrylic Magnetic Frame

Can the frame stand both vertically and horizontally?

Absolutely. The design supports dual-orientation display.

Product-Related Questions

Do you offer UV-resistant or anti-scratch acrylic?

Chinaplas Colored PMMA Cast Fluorescent Acrylic Sheet Translucent Green Orange Golden Acrylic Gold Mirror Acrylic Sheet Gloss

Our acrylic mirror sheets are made from 100% virgin PMMA material, offering superior reflectivity (up to 92%) while being 50% lighter and 10x more impact-resistant than traditional glass mirrors. Available in silver, gold, and bronze reflective finishes.

Wholesale Cheap Price High Mirror Effect Adhesive Silver Gold Acrylic Flexible Mirror Sheet

Our Adhesive Silver and Gold Acrylic Flexible Mirror Sheets are the perfect alternative to traditional glass mirrors, combining a high-reflection effect with lightweight, durable, and shatterproof properties. Made from premium-grade acrylic (PMMA), these flexible mirror sheets feature a self-adhesive backing, allowing for easy installation on walls, furniture, crafts, and decorative projects.

With their brilliant mirror-like finish, available in silver and gold, they add elegance, brightness, and a modern touch to any space. Whether you need mirrors for DIY projects, home decoration, or commercial displays, our flexible acrylic sheets deliver both beauty and functionality at an affordable price.

Wholesale Eco-Friendly 1.5mm 3mm Golden Luxury Acrylic Board Home Decor Gold Mirror Acrylic Sheets For Laser Cutting

Buy eco-friendly golden acrylic mirror sheets at wholesale prices. Available in 1.5mm & 3mm thickness, perfect for home décor, crafts, wedding decoration, signage, and laser cutting projects.

Wall Art Islamic Calligraphy acrylic mirror gold Wall Art Gold Color

Are you looking for an initial consultation, or do you have a specific project?

If you are interested our products and services, please leave us messages here to know more details. We will reply as soon as possible.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

Foshan Chinaplas Material Co.,ltd

Foshan Chinaplas Material Company Limited

FOSHAN CHINAPLAS MATERIAL CO.,LTD

Foshan Chinaplas Material Co.,ltd

CHINAPLAS ACRYLIC

Whatsapp: +8613927780518